Generation Mining Updates On Metallurgical Test Programs And Initiates A Pilot Plant

Toronto, Ontario – October 22, 2020 – Generation Mining Limited (TSX: GENM) (OTCQB: GENMF) (“Gen Mining” or the “Company”) is pleased to update on the continued progress of the Feasibility Study currently underway for the Marathon Palladium project in northwestern Ontario (the “Marathon Project”).

The Company previously reported on the Phase 1 bench-scale metallurgical testing program (news release dated August 20, 2020) that determined the recovery to be used for the Feasibility Study and the expected recoveries for the Project going ahead. The Phase 1 Metallurgical Testing program achieved the following results:

| 2020 Phase 1 Metallurgical Recovery 1 (as determined by 2020 Met Testing) |

PEA2 Metallurgical Recovery |

Variance |

|

|

Palladium (Pd) |

86.9% |

82.9% |

+4.0% |

|

Copper3 (Cu) |

93.0% |

90.0%3 |

+3.0% |

|

Platinum (Pt) |

84.2% |

74.5% |

+9.7% |

|

Gold (Au) |

72.4% |

73.2% |

-0.8% |

|

Silver (Ag) |

Not evaluated in this program |

71.5% |

n/a |

|

1 Recovery calculations are based on the established head grade of composite samples ranging in Cu, Pd, Pt, and Au head grade and involving multiple benchscale flotation tests. |

|||

In September 2020, the Company progressed to a Phase 2 metallurgical testing program, again at SGS Canada Inc. in Lakefield, Ontario. The Phase 2 Metallurgical Testing program is being overseen by Steve Haggarty, P.Eng., of Haggarty Technical Services (“HTS”) and Ausenco Engineering Canada Inc. (“Ausenco”) (acting as the Qualified Person for the upcoming metallurgical and processing sections of the Feasibility Study Technical Report). The goal of this program is to further define (i) the performance of the cleaning and scavenger flotation circuits, (ii) the optimal grind size in the regrind circuit and (iii) the overall validation of the circuit performance with a mini-pilot plant. The first two tasks have been completed. The initial locked cycle testing and a pilot plant program commenced mid-October and will be completed during November 2020.

The Phase 2 metallurgical and the pilot plant will involve three bulk sample composites with varying Palladium (Pd) and Copper (Cu) content from freshly excavated material in the Main Zone, W-Horizon, and a composite previous collected in 2012. The range in grade and material types will allow the Company to optimize process design criteria and Pd-Cu recovery, while advancing predictive Geo-Met modeling to estimate Life of Mine plan metal recoveries from the deposit.

The progress that has been realized on Phase 1 and Phase 2 testing to date:

- Optimized initial grind size and applied flotation reagents to maximize platinum group metals (PGM) and Cu recovery to rougher concentrate;

- Optimized rougher concentrate regrind size and cleaner circuit performance to maximize PGM-Cu capture to final concentrate;

- Confirmed the applicability of magnetic separation for pyrrhotite mineralization associated with the Marathon Palladium project to provide NSR optionality for separate PGM-Cu and iron sulfide-PGM-Cu concentrates;

- Confirmed the applicability of a cycloned coarse/fine fraction of rougher tailings that would be subject to additional regrinding to provide incremental PGM recovery for the project;

- Validated the performance of Woodgrove Direct Flotation Reactor (DFR) technology which would provide similar or improved PGM-Cu recovery at higher concentration ratios (lower mass pull);

- Implementation of DFR technology will decrease the footprint associated with the flotation portion of the processing plant; a smaller footprint will reduce the capital cost associated with the construction and is expected to decrease the plant operating costs and carbon footprint through reduced energy consumption;

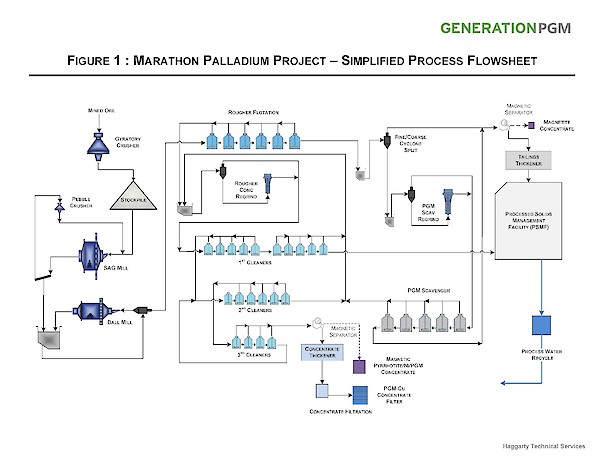

- Confirmed that the alternate flowsheet (Figure 1) for plant design has improved performance and operability over previously defined process concepts from the 2020 PEA (Technical Report 6 July 2020).

“We believe that the processing plant flowsheet is an improvement over the past design and the metallurgical testing programs have shown improved recoveries. The achieved successes and the validation of the flowsheet will be carried forward in Feasibility Study designs and into the subsequent detailed engineering phase. We see the achieved recoveries and overall design to be very positive for the overall Project”, stated Drew Anwyll, Chief Operating Officer, Generation Mining.

Figure 1 below is the processing plant flowsheet for the Marathon Project.

Figure 1: Processing Plant Flowsheet being used in the Feasibility Study

https://genmining.com/site/assets/files/3765/marathon_palladium_project_simplified_flowsheet.pdf

https://genmining.com/site/assets/files/3765/marathon_pgm_flotation_circuit_revd.pdf

The Phase 2 pilot plant testing will be completed during Q4, 2020 and is expected to fully validate the flowsheet, process design criteria, and confirm expectations for final concentrate grade and quality. The pilot plant test program (as a key component of Phase 2 Metallurgical test program) is not a requirement of NI43-101 and is being progressed to allow for improved clarity for the concentrate marketing and to proactively progress the future detailed engineering.

About the Company

Gen Mining’s focus is the development of the Marathon Palladium Project, the largest undeveloped platinum group metal Mineral Resource in North America. The Marathon property covers a land package of approximately 22,000 hectares, or 220 square kilometres. Gen Mining acquired a 51% interest in the Marathon Project from Sibanye Stillwater on July 10, 2019 and can increase its interest to 80% by spending $10 million over a period of four years. The 80% ownership is expected to be realized later in Q4 2020. As at the end of Q3 2020, approximately $8.7 million of the $10 million has been spent. Sibanye Stillwater has certain back-in rights that allow it to increase its interest in the Marathon Project back up to 51% in certain circumstances and subject to certain conditions after such time as Gen Mining has earned its 80% interest (see the Company’s press release of July 11, 2019 for more details).

Qualified Person

The scientific and technical content of this news release was reviewed, verified and approved by Drew Anwyll, P.Eng., M.Eng, Chief Operating Officer of the Company, and a Qualified Person as defined by Canadian Securities Administrators National Instrument 43-101 “Standards of Disclosure for Mineral Projects.”

For further information please contact:

Jamie Levy

President and Chief Executive

Officer

(416) 640-2934

(416) 567-2440

[email protected]

Forward-Looking Information

This news release includes certain information that may be deemed “forward-looking information” under applicable securities laws. All statements in this release, other than statements of historical facts, that address the ability of the Company and Sibanye Stillwater to vary their respective participating interests in the Marathon Project, Mineral Resource and Reserve potential, exploration activities and events or developments that the Company expects are forward-looking information. Although the Company believes that the expectations expressed in such statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the statements. There are certain factors that could cause actual results to differ materially from those in the forward-looking information. These include, among other factors, market prices, exploration and development successes, continued availability of capital and financing, and general economic, market or business conditions.

Investors are cautioned that any such statements are not guarantees of future performance and actual results or developments may differ materially from those projected in the forward-looking information. For more information on the Company, investors are encouraged to review the Company’s public filings at www.sedar.com. The Company disclaims any intention or obligation to update or revise any forward- looking information, whether as a result of new information, future events or otherwise, other than as required by law.